BurstCube Integration

BurstCube is a mission under development at NASA’s Goddard Space Flight Center in Greenbelt, Maryland. This CubeSat will detect short gamma-ray bursts, which are important sources for gravitational wave discoveries and multimessenger astronomy. The satellite is expected to launch in March 2024.

Julie Cox, a mechanical engineer at Goddard, handles BurstCube’s rectangular housing in this video. The aluminum structure is coated with gold chem-film, which protects the metal from corrosion. Openings in the housing are for connections to solar panels and other hardware BurstCube will need to navigate in space and send its data back to Earth.

Credit: NASA/Sophia Roberts

Goddard mechanical engineer Julie Cox demonstrates how different parts of the BurstCube satellite fit together in this video. She shows a 3D-printed bracket – featuring a miniature scientist – that will hold components in place within the spacecraft. She shows how a square GPS antenna attaches to one side of the satellite. She stacks the circuit boards that will process BurstCube’s data into a device for testing.

Credit: NASA/Sophia Roberts

The silver Teflon coated aluminum lid shown in this video features the BurstCube logo and a list of the mission’s partners: NASA’s Goddard Space Flight Center, University of Alabama Huntsville, George Washington University, ADNET Systems, Trident Vantage System, NASA’s Marshall Space Flight Center, Naval Research Laboratory, University of Maryland College Park, Universities Space Research Association, University College Dublin, University of the Virgin Islands, Clemson University, and Los Alamos National Laboratory. The openings in the lid are for sensors BurstCube will need to collect data and navigate.

Credit: NASA/Sophia Roberts

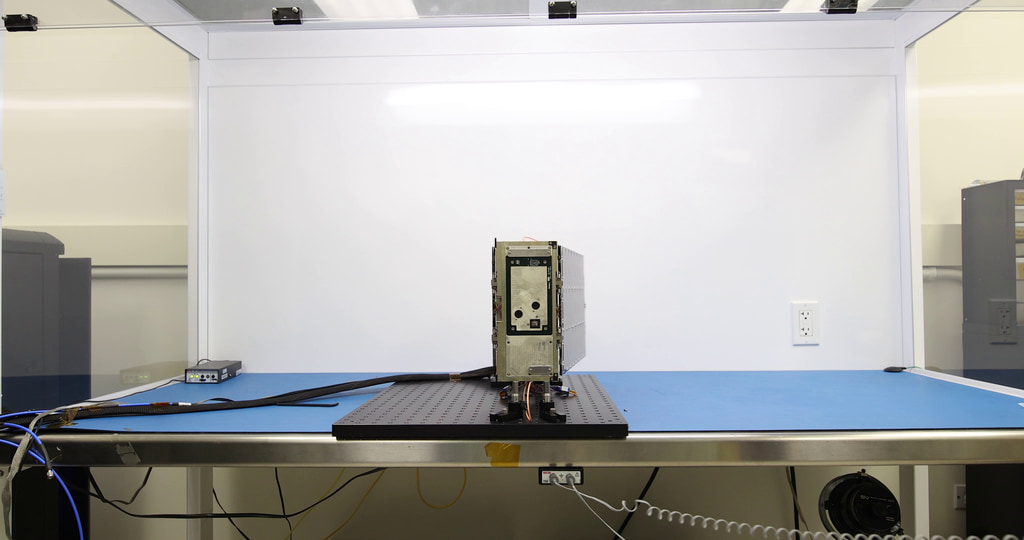

Circuit boards are inserted into a card stack, like the one shown here, before they’re tested and attached to the baseplate of BurstCube’s spacecraft housing.

Credit: NASA/Sophia Roberts

An individual circuit board rests on a lab bench. The BurstCube mission will use these boards to process data collected from gamma-ray bursts, the most energetic explosions in the cosmos.

Credit: NASA/Sophia Roberts

Cables connect a card stack to the Electrical Power Subsystem for testing. Even small missions like BurstCube require multiple rounds of verification before they’re ready for launch.

Credit: NASA/Sophia Roberts

Goddard mechanical engineer Julie Cox makes BurstCube “light tight” by pressing aluminized tape over joints, screws, and other miniscule gaps in the instrument suite, as shown in this video. Gamma rays can travel through the covering and into the detectors, but any stray visible light could trigger a false reading. The team will test the instrument’s light tightness by shining a laser over all its surfaces.

Credit: NASA/Sophia Roberts

Julie Cox, a mechanical engineer at Goddard, presses aluminized tape to the BurstCube instrument. Under the tape, Cox has also “staked” the screwheads, which involves the application of a special kind of glue that fills in any potential gaps, to help make it light tight.

Credit: NASA/Sophia Roberts

In this timelapse video from 2023, Goddard engineers Julie Cox and Paul Lestingi prepare the rectangular aluminum frame that will house BurstCube’s internal components and lower it onto the baseplate. The first section shows Cox staking screwheads, which involves the application of a special kind of glue that ensures the screws don’t loosen and fills in any potential gaps to help make the spacecraft housing light-tight. The second section shows the same action from above. In the next, Cox and Lestingi carefully settle the frame over BurstCube’s internal components.

Credit: NASA/Sophia Roberts

The BurstCube spacecraft rests on a platform in a lab at NASA’s Goddard Space Flight Center in Greenbelt, Maryland, for science instrument calibration in this 2023 video. One short edge shows the mission logo and a list of partner institutions. Then, from left to right, Paul Lestingi (spacecraft electrical engineer), Lucia Tian (lead instrument engineer), and Pi Nuessle (doctoral researcher) brace and adjust the satellite. Another shot shows the BurstCube logo panel in more detail, and in the last, Lestingi carefully rotates the platform holding the spacecraft.

Credit: NASA/Sophia Roberts

Interior components of the BurstCube satellite appear in this photograph. BurstCube, a shoebox-sized satellite that will study some of the universe’s most powerful explosions, was designed and built at NASA’s Goddard Space Flight Center in Greenbelt, Maryland. The four circular detectors make up the mission’s gamma-ray detector.

Credit: NASA/Jeanette Kazmierczak

Alt text: This photograph shows the inside of a small spacecraft.

Descriptive text: A small, rectangular spacecraft sits with its interior revealed in this photograph. The left-hand side of the spacecraft is full of a colorful assortment of wires and components. The right-hand side is taken up by four gold circular objects tipped toward each other at 45-degree angles and connected at the base. The spacecraft is on a work bench with a variety of equipment visible on the sides and behind it, including a small digital thermometer, a red toolbox, and a microscope.

Credits

Please give credit for this item to:

NASA's Goddard Space Flight Center

-

Producers

- Sophia Roberts (Advocates in Manpower Management, Inc.)

- Scott Wiessinger (KBR Wyle Services, LLC)

-

Science writers

- Jeanette Kazmierczak (University of Maryland College Park)

- Francis Reddy (University of Maryland College Park)

-

Engineers

- Julie Cox

- Sean Semper (NASA)

-

Principal investigator

- Jeremy Perkins (NASA/GSFC)

-

Scientist

- Judith Racusin (NASA/GSFC)

Release date

This page was originally published on Monday, October 31, 2022.

This page was last updated on Friday, December 15, 2023 at 11:44 AM EST.